Efficiency Information Help

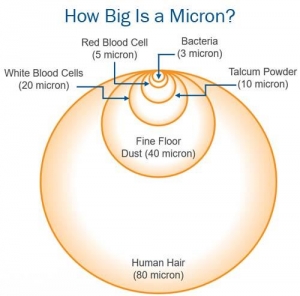

Hunter Multi-clone Dust Collectors are designed to operate between 2.5” and 3.5” of water pressure drop. Below 2.5” and efficiencies drop off. Above 3.5” and efficiencies drop off.

Contact Hunter for further assistance in this area.

Within this target operating pressure drop range Efficiency Curves are available depicting Collection Efficiencies versus Micron particle size distribution for your application.

Construction Specifications Help

Standard constructions typically include:

- All 3/16” plate Carbon Steel Casings & Hoppers

- ¼” Plate Internal Lower Tube sheet

- 3”x3” x ¼” Flanged Inlets and Outlets

- Cast Iron Tube Internals

- Bolted, Plated and Insulated Access Doors with Hazard Sign & Safety Chain

- SP-2&3 Exterior Surface Preparation with High Heat Silver or Dark Red paint.

Contact Hunter for further assistance in this area.

Custom Constructions may include:

- Higher Temperature Corten Steel versus Carbon Steel

- Thicker Plate construction, all ¼” for example

- Internal flow vanes for better flow distribution

- Wear and/or erosion shields made of throw away steel parts

- Higher BHN internal parts

Troubleshooting

Contact Hunter for a simple 1 page trouble shooting guide with an outline of Symptoms, Possible Causes, and Possible Solutions.

Operations, Maintenance & Installation Information

With every Hunter Industries Dust Collector order an electronic IO&M manual is emailed to the customer, tailored for your specific project and detailing:

- General Operation

- Internal Tube Assembly Care

- Outage Inspection Recommendations

- Hopper & Confined Space Information

- Receiving & Inspection Information

- Storage Guidelines

- Installation Comments

- Spare Parts Information

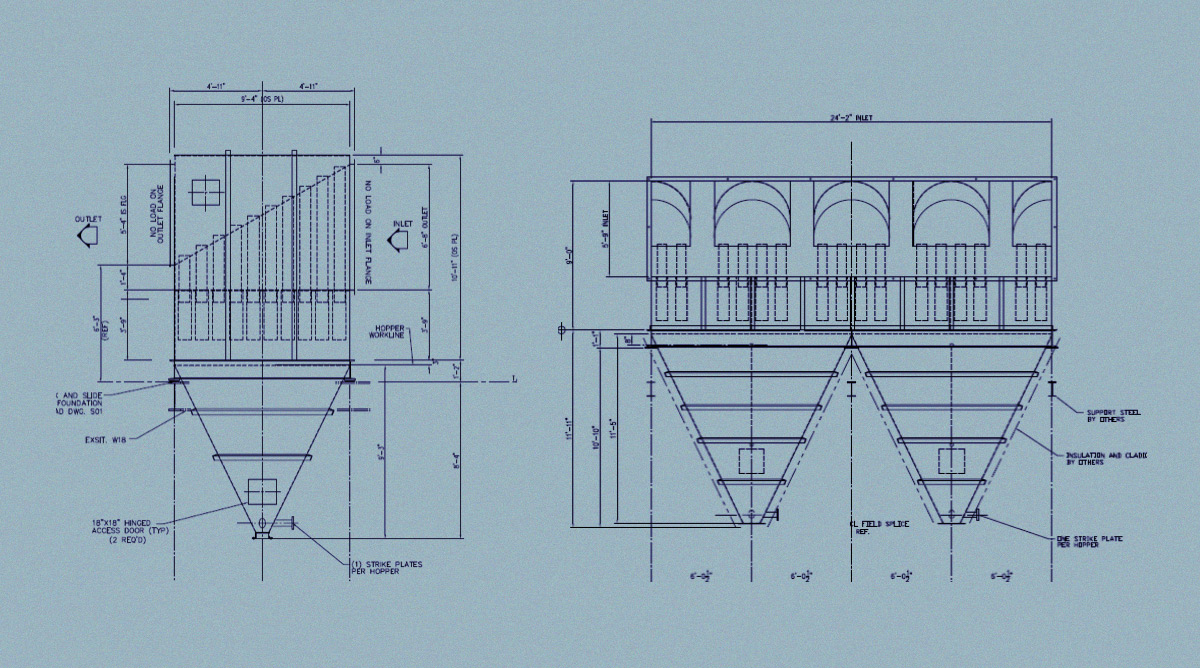

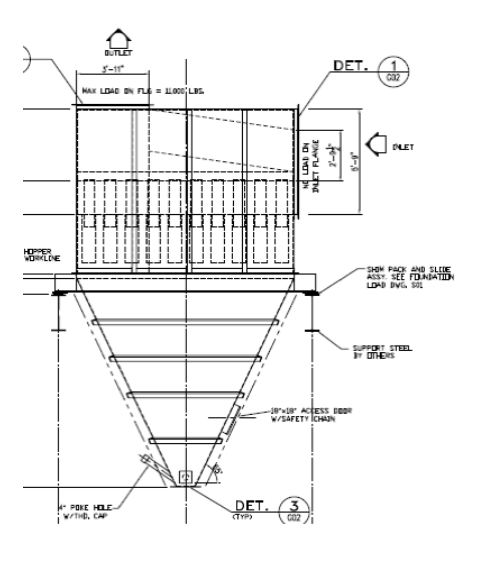

Preliminary General, Approval & Certified Arrangement Drawings

With every quote upon request, Hunter will email the customer a simple 1 page Plan and Elevation preliminary drawing providing overall width, length, height, and weight of the unit proposed.

With every order, Hunter will email the customer Approval Drawings, followed by Certified Drawings and any associated necessary Structural or Field Erection Assembly drawings.